AH(R)/HH/M(R)/L Slurry Pump

Product Description

AH, M, HH series slurry pump is types of horizontal Warman pump. Slurry transportation is at the heart of a successful mine site operation, making it crucial for your pumping equipment to be up to the task. AH, M, HH series Warman pumps also provides a complete selection for most duties in the mill, from the cyclone feeds to regrind, flotation and tailings.

A wide variety of impellers and shaft seals provide a perfect fit for a wide range of applications. The pump provides excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost. It offers extended wear life, reduced maintenance, outstanding availability and high performance pumping across mining, chemical, and industrial applications. Designed to offer high performance, reliability and low total cost of the owner, our Warman pump replaced will solve your slurry problems and improve your slurry transportation process and save you more operating costs.

Product Features

Main Application

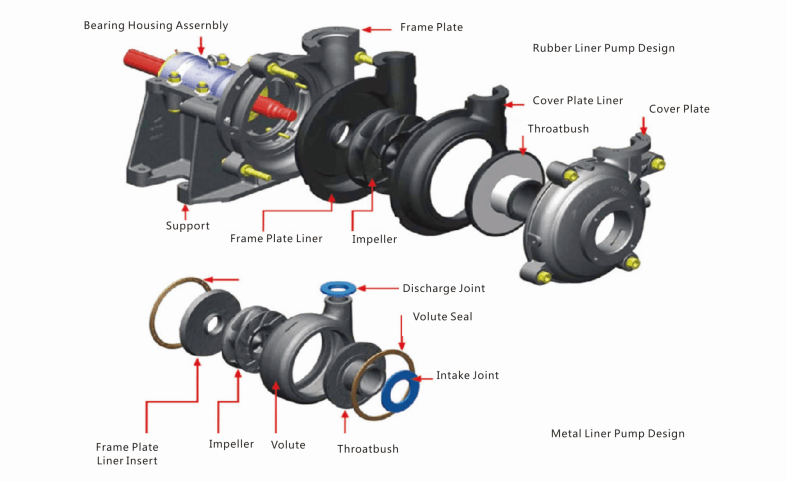

■ The spares of the Warman pumps replaced can be changeable with Warman original. Also, the wetted parts’ material can be optional as metal, rubber, PU or ceramic according to the application.

- Bearing assembly – a large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame.

- Volute Liners-easily replaceable liners are bolted, not glued, to the casing for positive attachment and ease of maintenance. Hard metal liners are completely interchangeable with pressure molded elastomer.

- Elastomer seal rings back all liner joints.

- Pump Case–Casing halves of cast or ductile iron with external reinforcing ribs provide high operating pressure capabilities and an extra measure of safety.

- Impeller–front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomer impellers are completely interchangeable.

- Cast in impeller threads requires no inserts or nuts. High efficiency and high head designs are also available.

- Throatbush–wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal.

- One-piece frame – a very robust one-piece frame cradles the cartridge type bearing and shaft assembly.

- An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance

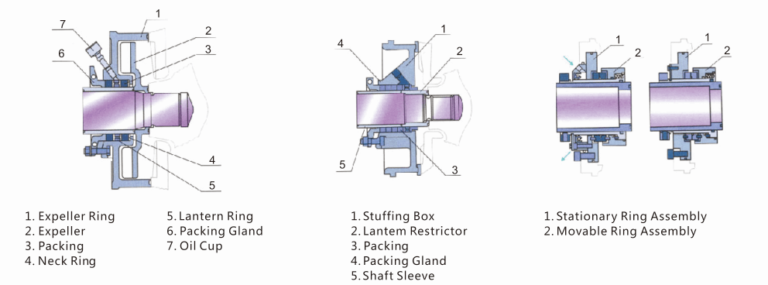

■ The shaft seals for the pumps can be adoptable of gland seal, expeller seal or mechanical seal

■ The discharge can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications

Type AH(R), HH, M(R) Warman pump are widely used in handling abrasive or corrosive slurry in the metallurgical, mining, coal, power, building material, and other industrial departments etc, for a range of mill duties, from dirty water to the most difficult water flushed crusher services, large particle slurries, gravel and many abrasive applications

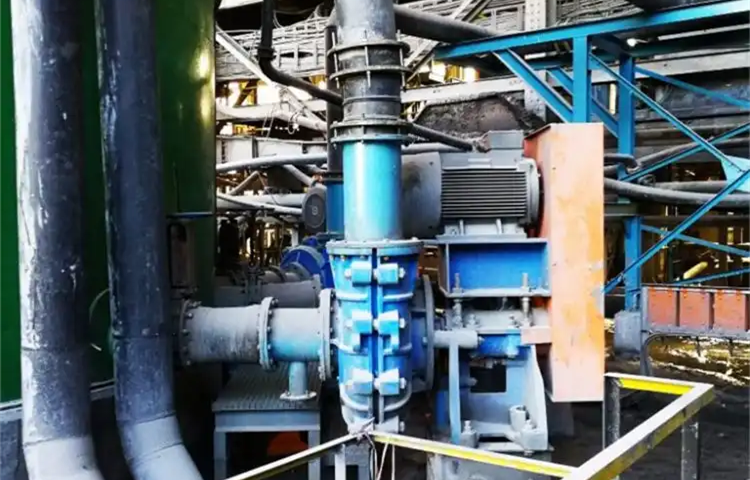

Slurry Pump Live Application

AH Slurry Pump Construction Design

AH Slurry Pump Shaft Seal Design

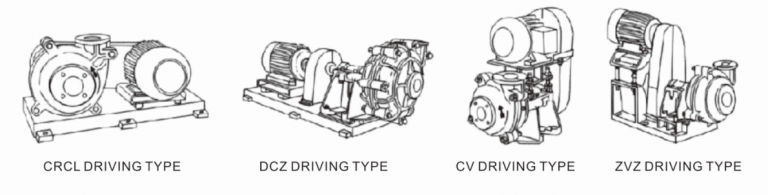

Slurry Pump Bracket Type Description

| Bracket Type | A | B | C | D | E | R | F | G | S | T |

| Allowable Max Power(kw) | 7.5 | 15 | 30 | 60 | 120 | 300 | 260 | 600 | 560 | 1200 |

| Bracket Weight(kw) | 17 | 24 | 45 | 77.5 | 154 | 228 | 555 | 1006 | 546 | 1156 |

| Shaft Water Volume | 0.15 | 0.25 | 0.35 | 0.55 | 0.70 | 0.70 | 0.70 | 1.20 | 1.20 | 1.60 |

AH Slurry Pump Transmission Type

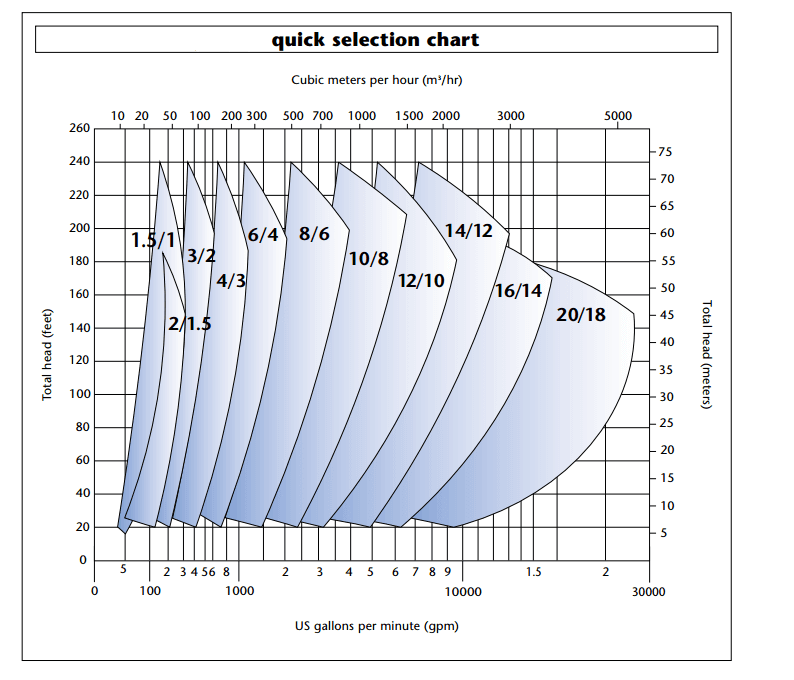

Selection & Performance Chart

AH Slurry Pump Performance Chart

| Pump Model | Allowable Max.Power (kw) |

Capacity m³/h |

L/S | Head H(m) |

Speed n(r/min) |

Max.EFF.(%) | NPSH (m) |

Impeller (mm) |

| 1.5/1B-AH | 15 | 12.6-28.8 | 3.5-8 | 6-68 | 1200-3800 | 40 | 2-4 | 152 |

| 2/1.5B-AH | 15 | 32.4-72 | 9-20 | 6-58 | 1200-3200 | 45 | 3.5-8 | 184 |

| 3/2C-AH | 30 | 39.6-86.4 | 11-24 | 12-64 | 1300-2700 | 55 | 4-6 | 214 |

| 4/3C-AH | 30 | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4-6 | 245 |

| 4/3D-AH | 60 | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4-6 | 245 |

| 6/4D-AH | 60 | 162-360 | 45-100 | 12-56 | 800-1550 | 65 | 5-8 | 365 |

| 6/4E-AH | 120 | 162-360 | 45-100 | 12-56 | 800-1550 | 65 | 5-8 | 365 |

| 8/6E-AH | 120 | 360-828 | 100-230 | 10-61 | 500-1140 | 72 | 2-9 | 510 |

| 8/6R-AH | 300 | 360-828 | 100-230 | 10-61 | 500-1140 | 72 | 2-9 | 510 |

| 10/8ST-AH | 560 | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4-10 | 686 |

| 12/10ST-AH | 560 | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 6 | 762 |

| 14/12ST-AH | 560 | 1260-2772 | 350-770 | 13-63 | 300-600 | 77 | 3-10 | 965 |

| 16/14TU-AH | 120 | 1368-3060 | 380-850 | 11-63 | 250-550 | 79 | 4-10 | 1067 |

| 20/18TU-AH | 1200 | 2520-5400 | 700-1500 | 13-57 | 200-400 | 85 | 5-10 | 1370 |

| 1.5/1B-AH | 15 | 10.8-25.2 | 3-7 | 7-52 | 1400-3400 | 35 | 2-4 | 152 |

| 2/1.5B-AH | 15 | 25.2-54 | 7-15 | 5.5-41 | 1000-2600 | 50 | 2.5-5 | 178 |

| 3/2C-AH | 30 | 36-75.6 | 10-21 | 13-39 | 1300-2100 | 55 | 2-4 | 213 |

| 4/3C-AH | 30 | 79.2-180 | 22-50 | 5-34.5 | 800-1800 | 59 | 3-5 | 245 |

| 4/3D-AH | 60 | 79.2-180 | 22-50 | 5-34.5 | 800-1800 | 59 | 3-5 | 245 |

| 6/4D-AH | 60 | 144-324 | 40-90 | 12-45 | 800-1350 | 65 | 3-5 | 365 |

| 6/4E-AH | 120 | 144-324 | 40-90 | 12-45 | 800-1350 | 65 | 3-5 | 365 |

| 8/6E-AH | 120 | 324-720 | 90-200 | 7-49 | 400-1000 | 65 | 5-10 | 510 |

| 8/6R-AH | 300 | 324-720 | 90-200 | 7-49 | 400-1000 | 65 | 5-10 | 510 |

| 10/8ST-AH | 560 | 540-1188 | 150-330 | 12-50 | 400-750 | 75 | 4-12 | 686 |

| 12/10ST-AH | 560 | 720-1620 | 200-450 | 7-45 | 300-650 | 80 | 2.5-7.5 | 762 |

| 14/12ST-AH | 560 | 1152-2520 | 320-700 | 13-44 | 300-500 | 79 | 3-8 | 965 |

| 16-14TU-AH | 1200 | 1224-2754 | 340-765 | 9-43 | 250-450 | 82 | 3-8 | 1067 |

| 20-18TU-AH | 1200 | 2268-4860 | 630-1350 | 11-46 | 200-350 | 82 | 2-8 | 1372 |

| 10/8E-M | 120 | 540-1440 | 150-400 | 14-60 | 600-1000 | 73 | 4-10 | 549 |

| 10/8R-M | 300 | 540-1440 | 150-400 | 14-60 | 600-1000 | 73 | 4-10 | 549 |

| 1.5/1C-HH | 30 | 16.2-34.2 | 4.5-9.5 | 25-92 | 1400-2200 | 20 | 2-5.5 | 330 |

| 3/2D-HH | 60 | 68.4-136.8 | 19-38 | 25-87 | 850-1400 | 47 | 3-7.5 | 457 |

| 4/3E-HH | 120 | 126-252 | 35-70 | 12-97 | 600-1400 | 50 | 2-5 | 508 |

| 6/4F-HH | 260 | 324-720 | 90-200 | 30-118 | 600-1000 | 64 | 3-8 | 711 |

| 8/6S-HH | 560 | 468-1008 | 130-280 | 20-94 | 500-1000 | 65 | 4-12 | 711 |

Slurry Pump Selection Guide

Export Slurry Pump, Chemical Pump, Vertical Slurry Pump, Sand Pump

Our Company

Over the past 15 years, Minerco has offered our clients pumping solutions to trusted the world over. Our core team of professional engineers has perfected the centrifugal slurry pump design to give you the best product on the market. Our slurry pumps and spares are interchangeable with the Warman model and parts and come with a 100% risk-free guarantee.

Our Promise- Reliable Quality & Professional Service

Your satisfaction is our number one priority. We welcome your feedback and are always looking for opportunities to improve our service. Our business philosophy is simple:

Quality control– We want to assure you of the perfection of our products, which is why we employ in-house quality management and process inspection team.

Fast, reliable service– We aim to meet the demands of all of our customers quickly and effectively. Our work is not complete until you are satisfied.

Supply support capacity– We understand no two operations are the same and that different jobs require different tools- that is why we take pride in the fact that it is well-stocked with a wide, diverse range of products.

Competitive pricing– We believe we offer the best product possible for the cost.